Fasteners, including bolts, screws, and nuts, are essential components in a wide range of applications, from construction to automotive and aerospace industries. However, despite their critical role, fasteners are prone to failure due to various reasons. Understanding the causes of fastener failures and how to prevent them using products like Loctite thread lockers and anti-seize compounds can significantly enhance the reliability and longevity of assemblies.

Common Causes of Fastener Failures

Improper Installation

Over-Tightening: Exceeding the recommended torque can lead to fastener breakage or stripping of threads.

Under-Tightening: Insufficient torque can cause fasteners to loosen over time, leading to joint failure.

Incorrect Fastener Selection: Using the wrong type or grade of fastener for the application can result in inadequate performance or failure.

Fatigue

Cyclic Loading: Fasteners subjected to repeated loading and unloading can experience fatigue, leading to cracks and eventual failure.

Vibration: Continuous vibration can cause fasteners to loosen, especially if they are not properly secured.

Corrosion

Environmental Exposure: Fasteners exposed to moisture, chemicals, or salt can corrode, weakening their structural integrity.

Galvanic Corrosion: Occurs when different metals are in contact in the presence of an electrolyte, leading to accelerated corrosion of the anodic metal.

Mechanical Damage

Impact Loads: Sudden impacts or shocks can cause fasteners to shear or deform.

Misalignment: Poor alignment of mating parts can impose additional stress on fasteners, leading to premature failure.

Thermal Effects

Thermal Expansion and Contraction: Temperature fluctuations can cause fasteners to expand and contract, leading to loosening or stress fractures.

Heat Degradation: Prolonged exposure to high temperatures can weaken the material properties of fasteners.

Preventing Fastener Failures with Loctite Threadlockers

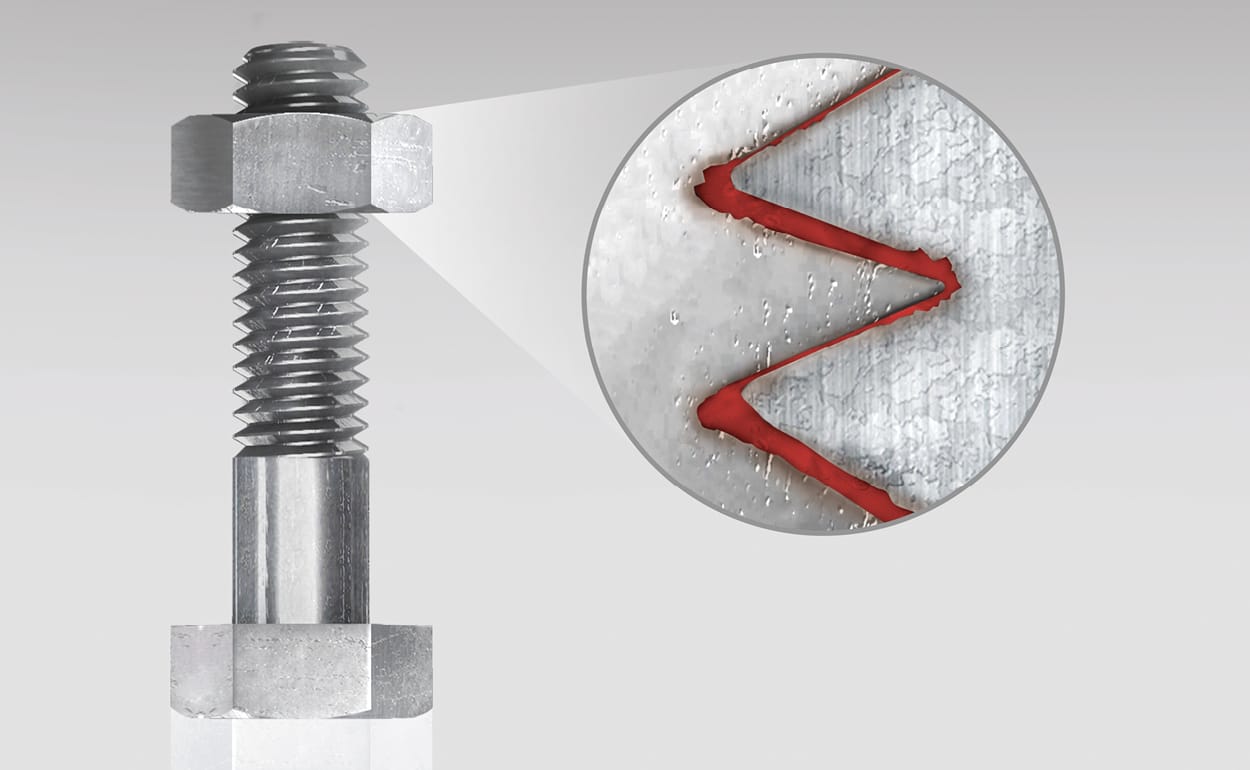

Loctite threadlockers are anaerobic adhesives that cure in the absence of air and in the presence of metal ions. They are designed to lock and seal threaded fasteners, preventing loosening due to vibration and shock. Here’s how they help prevent fastener failures:

Vibration Resistance

Secure Fit: Loctite threadlockers fill the gaps between threads, providing a secure fit that resists loosening due to vibration and cyclic loads.

Permanent Lock: Depending on the formulation, threadlockers can provide a permanent lock or allow for disassembly with standard tools, ensuring reliability in various applications.

Corrosion Protection

Sealing Capability: By filling the voids between threads, threadlockers prevent moisture and corrosive substances from penetrating, thereby reducing the risk of corrosion.

Environmental Resistance: Loctite threadlockers are formulated to withstand harsh environmental conditions, further enhancing the durability of fasteners.

Preventing Fastener Failures with Anti-Seize Compounds

Loctite Anti-seize compounds are lubricants designed to prevent galling, seizing, and corrosion in threaded connections. They are particularly useful in high-temperature and high-pressure environments. Here’s how they contribute to preventing fastener failures:

Prevention of Galling and Seizing

Lubrication: Anti-seize compounds provide a lubricating layer between threads, reducing friction and preventing galling and seizing during assembly and disassembly.

Ease of Disassembly: Fasteners treated with anti-seize can be easily disassembled, even after prolonged exposure to harsh conditions, reducing the risk of damage during maintenance.

Corrosion Resistance

Protective Barrier: Anti-seize compounds create a barrier that protects fasteners from moisture, chemicals, and other corrosive agents, thereby extending their service life.

Temperature Tolerance: Formulated to withstand extreme temperatures, anti-seize compounds prevent oxidation and corrosion at both high and low temperatures.

Enhanced Performance in Harsh Environments

High-Pressure Applications: Anti-seize compounds are ideal for use in high-pressure environments, where they help maintain the integrity of fasteners under extreme conditions.

Consistency in Performance: By providing a consistent coefficient of friction, anti-seize compounds ensure reliable torque application, reducing the likelihood of over-tightening or under-tightening.

Leave a comment

All comments are moderated before being published.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.